Ball Valves to rely on.

Welcome to Boehmer Valve – the official distributor of the German Böhmer Ball Valves. Located in the center of the oil and gas business in Humble near Houston, the warehouse offers the advantage of quicker delivery. In fact, its goal is to cut down delivery times; and provide genuine Böhmer German quality.

We offer a wide variety of Ball Valves for district energy networks, the gas, oil industry, and different industrial applications.

Our Ball Valves are available from 2 to 42-inch up to 600 class, for above-ground or buried service.

Fields of Applicaton for our Ball Valves

District Energy

District Heat

Power plants

Heat storage

Transfer stations

Pipelines

Cooling services

Oil & Gas

Oil & Gas

Pipelines

Tanks

Pressure regulating stations

Refineries

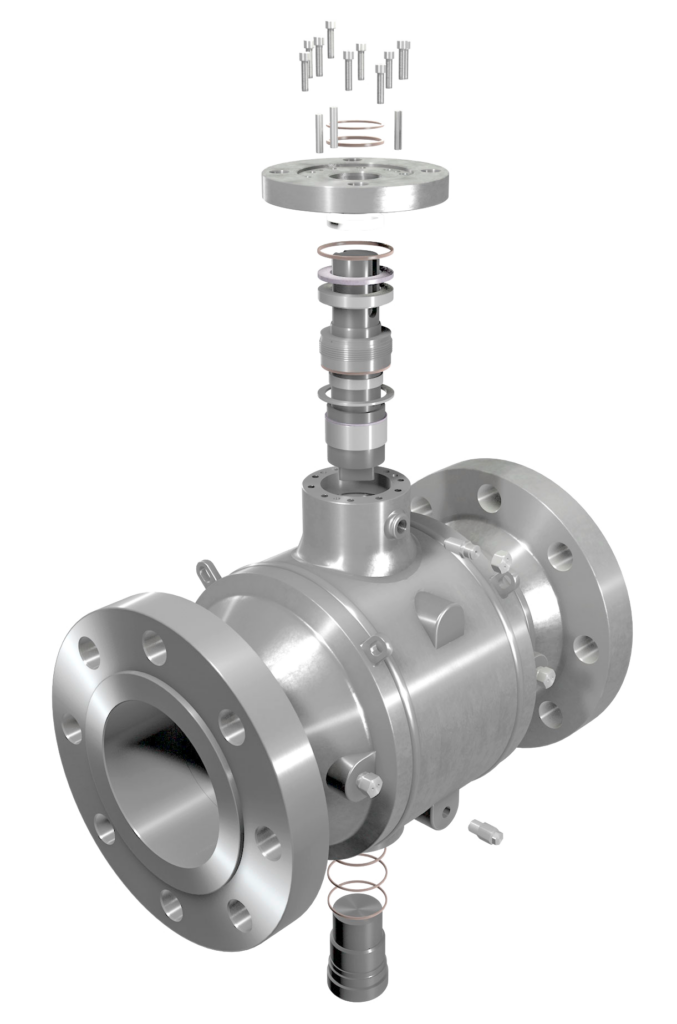

Discover the Construction Features of Böhmer Ball Valves

The pressure relief of the cavity is made possible via a vent connection. The seat ring on the upstream and downstream side thus ensures a tight seal to the cavity in the closed position (optionally also in the open position). This allows to check the tightness of the ball valve within a pressurized pipline.

If requested, we can deliver a sealant injection system for emergency sealing of the upstream, downstream and stem seals.

Electrically conductive connections between the inner parts of the ball valve and the body ensure that no static electricity can build up.

This design ensures fire safety according to international regulations such as API 6FA, API 607 and BS 6755 P 2.

Several independent sealing systems ensure sealing of the stem. The design prevents ejection of the stem while under pressure. That means that the three upper seals can be replaced under full pipeline pressure in both the open and closed positions.

Trunnion-mounted balls are standard features of Böhmer ball valves with a nominal diameter of 3“ and larger. In addition, self-lubricating bearings ensure low torques even at high pressure.

Construction features vary depending on model and order

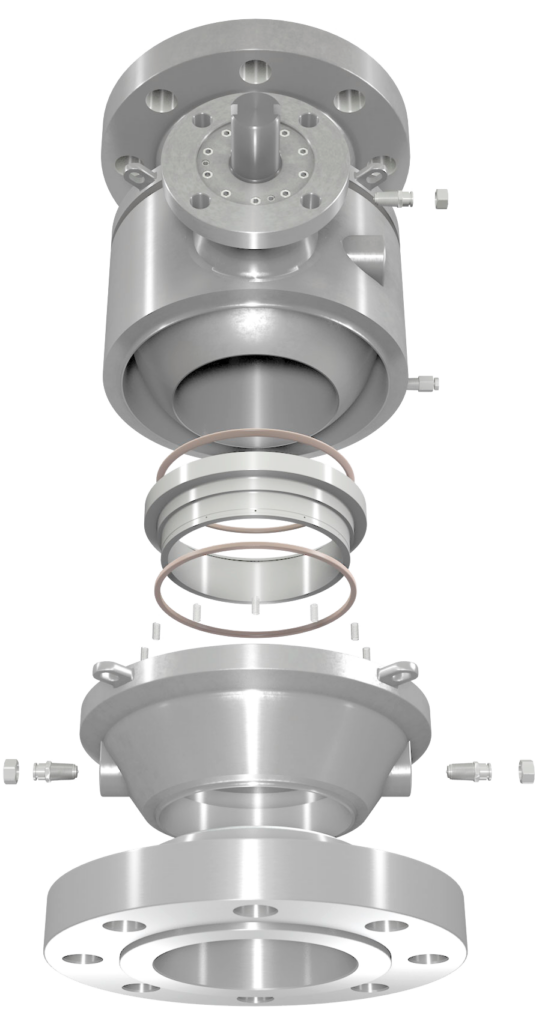

The sealing function is ensured by sealing rings made of plastic. A multitude of available materials (PTFE, PA, PEEK, etc.) enable a wide spectrum of applications and suitability for various fluids. Ball valves with plastic seals also feature low torques.

Metal to metal seals are especially well suited to high pressures and temperatures. They are resistant to wear and not sensitive to dirt and Sediments.

PMSS seat rings (Primary Metal Secondary Soft) are metallic seat rings with elastomer inserts. The combination of metallic gaskets with elastomers allows a wide range of applications as well as high wear resistance and less sensitivity to dirt.

The standard design of Böhmer ball valves includes spring-supported seat rings that guarantee tight sealing even with minimal pressure in the pipeline. Thanks to the seat ring design, the seating force of the seals is supported by the pipeline pressure and the seat ring force increases proportionally to the operating pressure.

Construction features vary depending on model and order

"Since 1956 we manufacture

nothing but

Ball Valves,

but we make it right"

Dr. Thomas Böhmer, Managing Director

Product Range & Examples

Design type

Böhmer produces ball valves fully welded or with split-body housings

Diameter

Modern production facilities allow us to manufacture in nominal diameters up to 56 inches (DN1400)

Connection type

Böhmer ball valves are available in accordance with DIN and ANSI standards with welding ends, flanges, threaded connections.

Dimensioning

The dimensions correspond to the common DIN and ANSI standards or your individual requirements.

Actuation

Depending on the application, our ball valves are actuated with hand levers, gearboxes or automatic drives

Design

Parameters such as pressure and temperature of the medium significantly determine the construction of the valve.

Materials

Our experienced technicians know the material combinations in order to shut off even critical media safely.

Coating

Optionally, we provide our fittings with various insulation or protective coatings.

Options & Features

We provide the valve with all the features that enable efficient and safe use.

Certifications

Our products are tested according to the guidelines you demand and delivered with corresponding certificates.

Burried Ball Valve for District Energy

/// with welding ends

/// Suitable for hot water & steam

/// Sizes: DN 25 - DN 1200

/// Pressure: PN 25

/// full or reduced bore

District Energy Ball Valve

/// with flanges

/// long pattern

/// Suitable for hot water & steam

/// Sizes: DN 15 - DN 100

/// Pressure: PN 25

District Energy Ball Valve

/// with weld ends

/// Suitable for hot water & steam

/// Sizes: DN 32 - DN 1000

/// Pressure: PN 25

/// Full- or reduced bore

District Energy Ball Valve

/// with weld ends

/// Suitable for hot water & steam

/// Sizes: DN 15 - DN 1200

/// Pressure: PN 25

/// Full- or reduced bore

Safety Shut-off Unit (SAE)

/// Sizes: up to 45''

/// The spring loaded drive closes the SAE when the measured gas pressure rises above the set maximum permissible gas pressure of the pipeline in 2 seconds

Odorizing Nozzle exchange Valve

/// Ball valve with window & injection nozzle connector - developed to simplify injection nozzle maintenance and service.

Pipline Ball Valve

/// fully welded

/// for burried service

/// Diameter 48''

/// ANSI Class 600

Split Body Ball Valve

/// Information follows

We are Boehmer

Get to know us!

Read more about us and our Products

Get in Touch

- BOEHMER VALVE Inc.

- 2014 S. Houston Ave, Humble, TX 77396

- +1 346 301 6600